America’s abandoned foundry towns tell a powerful story of industrial rise and decline. You’ll find these ghost towns throughout the Rust Belt, where post-Civil War manufacturing once thrived on abundant resources and railway connections. As you explore, you’ll encounter company-built neighborhoods, culturally divided communities, and environmental damage from unchecked industry. Despite their collapse from globalization and market shifts, many former foundry communities are experiencing remarkable revivals through economic diversification and adaptive reuse of historic structures.

Key Takeaways

- Foundry towns thrived during America’s industrial revolution, leading global manufacturing by 1900 before declining due to globalization and technology changes.

- These specialized communities experienced economic life cycles from rapid growth to devastating contraction, leaving abandoned industrial landscapes.

- Neighborhoods in foundry towns were strictly organized by occupation, ethnicity, and race, creating distinct cultural enclaves.

- Abandoned foundries left environmental hazards including groundwater contamination and airborne toxins causing elevated health risks in surrounding communities.

- Former industrial towns are being revitalized through economic diversification, adaptive reuse of facilities, and collaboration between private and public sectors.

The Birth of America’s Industrial Heartland

While the United States was still recovering from the Civil War, a remarkable industrial transformation was taking shape across its northern regions.

From 1870 to 1970, a manufacturing belt formed a vast parallelogram stretching from Baltimore to Maine, west to Wisconsin, and south to Missouri.

This industrial heartland capitalized on natural advantages: abundant iron ore from Michigan, accessible via the Great Lakes, and plentiful coal reserves that fueled foundry innovations.

The Civil War accelerated this growth through a national currency and railway development. By 1900, America captured half the world’s manufacturing capacity, surpassing Britain in steel and coal production.

The Civil War’s aftermath unleashed America’s industrial might, propelling it past Britain to dominate global manufacturing by century’s end.

Pittsburgh, Cleveland, and Chicago emerged as powerhouses, while Detroit became the “Motor City.”

These centers witnessed intense labor movements as rapid urbanization transformed small towns into industrial giants. The region’s identity was shaped by blue-collar workers who proudly considered themselves middle class despite the challenging factory conditions. Companies thrived with favorable transportation routes that connected manufacturing hubs to markets across the country.

Rise and Fall: The Economic Life Cycle of Foundry Communities

You’ll discover that foundry towns initially thrived through rapid industrial expansion, with companies controlling not just production facilities but entire communities supporting peak growth rates of 16% annually.

These industrial powerhouses later experienced maturation as growth slowed to around 6% annually, prompting investment shifts toward facility upgrades and product diversification while improving civic infrastructure. The Phoenix Iron Company exemplified this evolution when transitioning from nail production to large-scale iron manufacturing in the early 1800s. Oakland demonstrated similar patterns with its metal working sector becoming the second leading industry after food processing, establishing specialized machine shops and foundries primarily along the estuary-rail corridor.

The inevitable decline phase struck when globalization and technological disruption triggered manufacturing job losses of up to 38% in some communities, creating cascading effects of population exodus, deteriorating services, and widespread economic hardship.

Golden Age Industries

During the industrial revolution’s apex, foundry towns represented America’s manufacturing prowess, transforming from small settlements into bustling economic hubs virtually overnight. Operating around the clock, these towns employed thousands, with foundry work accounting for over half of local jobs during peak years.

The golden age saw remarkable foundry innovations in casting processes—from simple pipes and stoves to complex machinery components. Industrial craftsmanship flourished as cupola furnaces and steam power dramatically increased production capacity. The introduction of John Wilkinson’s cupola in 1794 revolutionized metal melting capabilities and increased production efficiency. These foundries utilized permanent mold casting and other techniques similar to modern operations.

You’d find thriving ancillary businesses supporting the main operations: machine shops, toolmakers, and transport services.

Workers earned premium wages compared to rural areas, attracting skilled labor and immigrants seeking economic freedom. The foundry’s importance extended beyond employment, fostering distinct working-class neighborhoods with company housing, schools, and cultural institutions that celebrated a shared industrial heritage.

Boom-to-Bust Transitions

The gleaming prosperity of America’s foundry towns would prove as fragile as it was remarkable.

You’d witness communities flourishing during industrial booms, then collapsing when market volatility struck, with demand swings exceeding 50% in typical business cycles.

These specialized economies lacked diversification, making them vulnerable to technological obsolescence and global competition.

When automation arrived or commodity prices plummeted, unemployment soared and populations fled.

Towns that had rapidly expanded during wartime production faced devastating contractions during peace.

The shift toward monetarist policies after 1979 further devastated many foundry communities as interest rates soared, making capital investments prohibitively expensive.

Much like in the UK, where cities such as Birmingham and Sheffield became epicenters of foundry innovation during the Industrial Revolution, these American towns experienced similar patterns of rise and decline.

Community resilience varied dramatically.

Some towns disappeared entirely when foundries closed, while others demonstrated economic adaptation by repurposing industrial infrastructure or developing new sectors.

The most successful transformations occurred where communities anticipated change rather than resisting it, developing alternative industries before complete collapse became inevitable.

Aftermath and Recovery

When foundry towns faced industrial collapse, their recovery trajectories diverged dramatically based on human capital and regional economic factors.

You’ll find that communities with higher percentages of college-educated residents adapted more successfully, experiencing 3% greater employment growth per decade.

Educational attainment proved decisive for economic diversification. While cities in the top education quartile grew during deindustrialization, less-educated communities suffered deeper employment losses.

The labor market recovery varied markedly by country—47% of German manufacturing hubs achieved full recovery by 2010, compared to only 17% in America’s Rust Belt.

Recently, left-behind US counties have shown promising rebounds, with job growth four times faster between 2020-2023 than in previous years. These counties are showing signs of economic restructuring rather than relying on new firms or expansions from large employers.

Local leaders have attracted new employers through tax abatements, though environmental contamination remains a considerable barrier to redevelopment in many former foundry communities.

Manufacturing dependency significantly increased vulnerability, with a 1 standard deviation increase in initial manufacturing share resulting in a 2.7% decrease in total employment growth per decade.

Daily Life in the Shadow of the Smokestacks

In foundry towns, your entire day was dictated by the factory whistle, which marked not just shift changes but mealtimes, school schedules, and community events.

You’d likely work alongside several generations of your family—fathers, sons, uncles, and cousins shared not just bloodlines but also burns, calluses, and lung damage from the same furnaces.

Your social circles remained tightly intertwined with your working life, as company-sponsored baseball teams, musical groups, and holiday celebrations reinforced the community’s complete economic dependence on the mill.

Factory Whistle Rhythms

Life in foundry towns revolved around the authoritative blasts of factory whistles, which established the cadence of daily existence for generations of industrial workers.

You’d hear distinct whistle signals at 7am, noon, 1pm, and 5pm, creating a shared auditory experience that synchronized entire communities.

Before personal timepieces became common, these steam-powered whistles—operating at 100-300 psi—served as the communal clock.

Five minutes before lunch breaks at noon and 1pm, you’d hear the preliminary alert, signaling you to finish your tasks.

During wartime, these same whistles doubled as emergency communication systems, with specific patterns indicating alerts or all-clears.

Worker synchronization wasn’t just practical—it became the rhythmic backbone of industrial towns, structuring not just labor but your entire day’s possibilities.

Multigenerational Workforce Communities

Though seemingly isolated from the outside world, multigenerational workforce communities in foundry towns formed intricate social ecosystems shaped by deliberate corporate design.

You’d find yourself living in housing that instantly revealed your status—supervisors in better homes, miners in identical cheap structures, with neighborhoods strictly segregated by race and ethnicity.

The multicultural dynamics were deliberately engineered through recruitment strategies creating a “judicious mixture” of workers to prevent unified organization:

- European immigrants establishing their own cultural institutions within confined spaces

- African Americans fleeing southern sharecropping finding alternative yet segregated opportunities

- Native white workers occupying separate residential clusters

- Families replacing bachelor workforces after 1910 for stability

- Diverse ethnic groups forming separate fraternal orders despite proximity

Despite these divisions, community resilience emerged through shared experiences in company-controlled environments stretching along railroads between mountain walls.

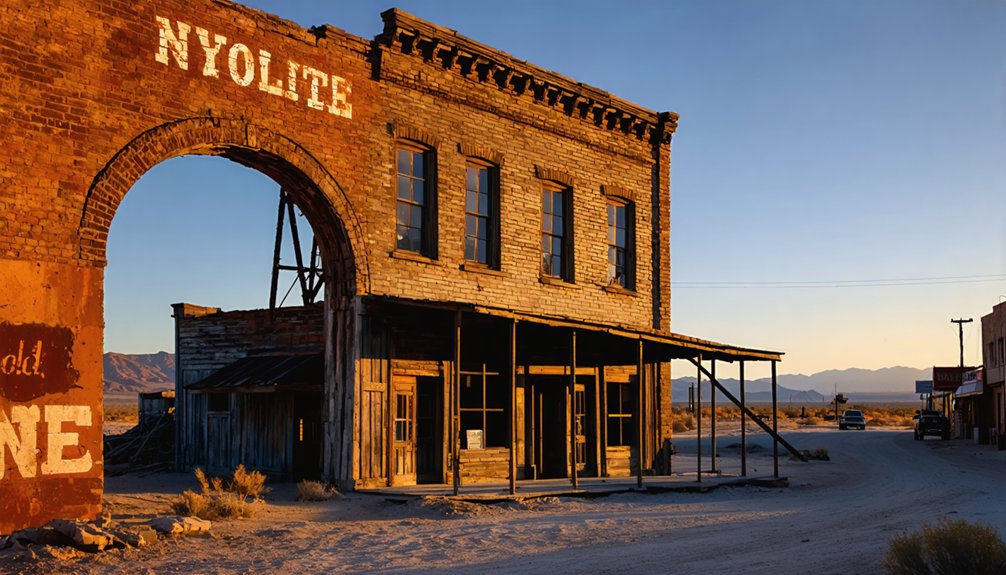

Ghost Towns of the Industrial Revolution

During the explosive growth of the Industrial Revolution, foundry towns emerged rapidly across landscapes previously dominated by agriculture and small-scale craft production.

These settlements ballooned quickly around single industries—iron smelting, coal mining, or steel production—only to face abandonment when resources depleted or economic shifts occurred.

The rise and fall of industrial towns hinged entirely on the health of their singular economic lifelines.

You’ll find these ghost town legends scattered along abandoned rail corridors, their fates sealed when transportation networks rerouted or when technological innovations made their operations obsolete.

Industrial archeology reveals company towns where everything from housing to churches fell under corporate control.

When depression struck or wartime demands subsided, populations fled, leaving behind remnants of once-thriving communities.

What made these towns particularly vulnerable was their dependence on singular economic drivers—when the foundry closed, everything collapsed, creating the silent industrial ghosts you can still explore today.

Environmental Legacy and Toxic Aftermath

While abandoned foundry towns stand as historical monuments to industrial progress, they simultaneously harbor a toxic legacy that continues to poison surrounding ecosystems and communities decades after operations cease. This toxic heritage disproportionately affects marginalized populations, raising critical environmental justice concerns.

When you visit these sites, you’ll encounter:

- Mining waste seeping heavy metals like arsenic and chromium into groundwater

- Airborne dust carrying contaminants from unpaved streets and industrial debris

- Abandoned structures leaching chemicals from decades of spills and improper disposal

- Residential areas with elevated cancer and respiratory disease rates

- Community activism fighting against governmental inaction and delayed remediation

Despite regulatory oversight, cleanup efforts often focus only on “hotspots,” leaving residual contamination that undermines revitalization efforts and perpetuates health risks for generations.

Rust Belt Rebirth: Revitalization Efforts in Former Factory Towns

After decades of decline, former factory towns across America’s Rust Belt are experiencing remarkable revivals through strategic economic diversification and innovative repurposing of industrial infrastructure.

You’ll find cities like Pittsburgh transforming old steel mills into high-tech research centers, while Akron leverages its tire-making expertise to become a polymer science hub.

The urban renewal process thrives on cross-sector collaboration, with private leaders and public officials forming cohesive teams.

In Grand Rapids, this approach yielded impressive job growth, while Allentown capitalized on its proximity to New York City.

Communities preserve their industrial heritage through adaptive reuse—converting historic factories into modern facilities with sustainable features like rainwater collection systems and high-performance glazing.

Tax incentives, workforce development programs, and state-sponsored placemaking initiatives further fuel these remarkable transformations.

Capturing the Stories: Documenting Foundry Town Heritage

Beyond the physical revitalization of America’s foundry towns lies an equally important effort: the preservation of their cultural memory and industrial legacy.

Through urban exploration and oral histories, dedicated individuals are ensuring these industrial narratives don’t fade into obscurity.

You’ll find documentation efforts taking many forms:

- Urban explorers photographing abandoned sites like the Aerosol Techniques factory in Milford

- Historical societies preserving blueprints and floor plans of places like West Point Foundry

- Local residents sharing personal memories of life in company towns like Jaite Mill

- Digital platforms showcasing images and findings from Troy’s ironworks

- Community-led oral history projects recording firsthand accounts of foundry closures

These preservation initiatives create a thorough record of industrial America’s rise and fall, connecting you to a tangible past that might otherwise be lost.

Frequently Asked Questions

What Role Did Child Labor Play in Foundry Town Economies?

Like cogs in rusted machines, you’d find children’s exploitation was an economic necessity in foundry towns, providing essential family income while keeping production costs low through their cheap, small-sized labor.

How Did Weather Patterns Affect Foundry Operations and Worker Safety?

Weather impacts on foundries were significant – extreme cold caused rapid metal solidification creating defects, while heat reduced your productivity and created safety hazards. You’d face dangers from both temperature extremes without climate control.

What Superstitions or Folklore Emerged Specifically in Foundry Communities?

You’d find ghost stories about iron spirits haunting failed castings, protective rituals involving scrap metal, and beliefs that blacksmiths could mediate between worlds through their mastery of transformative metalworking processes.

How Did Foundry Towns Handle Medical Emergencies Before Modern Healthcare?

You’d rely on basic first aid from company doctors, community support from neighbors, and traditional remedies. Transportation by wagon and limited communications meant emergency response was slow and rudimentary in foundry towns.

What Recreational Activities Were Unique to Foundry Town Communities?

Over 70 artists gathered at Nevada City Craft Fair! You’d find unique community festivals in repurposed foundry buildings, Victorian Christmas celebrations, local sports leagues like the Foundry Giants, and psychic fairs building social bonds.

References

- https://canals.org/2023/12/13/corridor-company-towns/

- https://dnrhistoric.illinois.gov/research/sitepages/timeline.html

- https://socialwelfare.library.vcu.edu/organizations/labor/company-towns-1890s-to-1935/

- https://en.wikipedia.org/wiki/List_of_North_American_settlements_by_year_of_foundation

- https://clarksvillefoundry.com/about-us/timeline-2/

- https://www.manufacturing.net/labor/blog/22879058/the-abandonment-of-cities-and-towns-in-the-heartland

- https://philadelphiaencyclopedia.org/essays/industrial-neighborhoods/

- https://www.gilderlehrman.org/history-resources/online-exhibitions/timeline-rise-industrial-america-1877-1900

- https://heartlandforward.org/case-study/perspectives-on-defining-the-american-heartland/

- https://www.britannica.com/place/Rust-Belt