When you explore vanished manufacturing communities, you’ll find more than abandoned buildings—you’ll discover identities forged in steel mills and assembly lines. These towns face economic migration, aging workforces, and generational poverty after factory closures devastated their foundations. Beyond statistics lie human stories of displaced workers, lost craftsmanship, and resilient children inheriting both scars and strength. These rust belt narratives hold valuable lessons about preserving industrial heritage before it fades completely.

Key Takeaways

- Documenting personal narratives through oral histories captures the lived experiences of former workers before their stories are lost forever.

- Digital archives and 3D scanning preserve manufacturing techniques and craftsmanship that defined communities for generations.

- Cross-generational apprenticeships connect youth with experienced artisans, transferring both skills and cultural identity.

- Community museums featuring local industrial artifacts help maintain collective memory and pride amid economic transition.

- Sustainable artisan networks merge traditional methods with modern technology, creating economic opportunities that honor manufacturing heritage.

The Silent Factory Towns: Mapping America’s Manufacturing Exodus

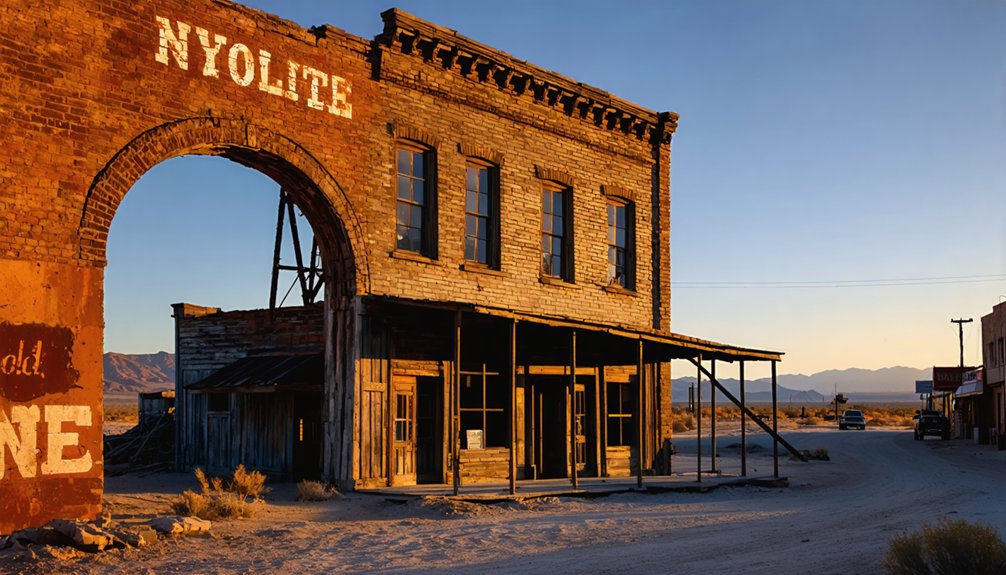

As the morning shifts once began with the rhythmic hum of assembly lines, now silence pervades the countless factory floors across America’s once-thriving manufacturing heartland.

The persistent silence of abandoned factories echoes the fading American dream across our industrial heartland.

You’ve witnessed the transformation first-hand: while the total number of manufacturing establishments increased to 401,000 by 2024, countless communities have suffered devastating factory closures.

The Midwest and Northeast bear the deepest scars, where single-industry towns face unemployment rates that drive economic migration.

Young residents abandon their heritage, seeking opportunity elsewhere. With each departure, local businesses fold, property values plummet, and vacant buildings multiply.

Manufacturing jobs have dwindled to just 9.3% of private sector employment, leaving community identities fractured. Rising costs and declining employment rates have further strained manufacturers struggling to maintain operations in these communities.

The exodus of experienced workers has created a brain drain crisis, with nearly 25% of remaining manufacturing workers being 55 or older.

Behind each statistic lies a town’s unique story – of prosperity, struggle, and the search for renewal.

Beyond Statistics: Human Stories of Deindustrialization’s Impact

When a factory whistle sounds for the final time, what truly vanishes beyond the paycheck?

You’re witnessing the unraveling of something deeply human—workplace families scatter, with 38% of displaced workers falling into hopelessness compared to just 5% of the employed.

Your community’s social fabric tears as gathering places disappear.

Former coworkers avoid one another, not from anger but from shared shame. The decaying industrial landscape becomes a daily reminder of what’s been lost. Cities like Youngstown once vibrant with steel production now face high crime rates and deteriorating urban infrastructure. This contrasts sharply with the industrial era’s low crime rates and social stability.

Yet within these wounded places, emotional resilience emerges.

Children of displaced workers inherit both scars and strength, maneuvering a world their parents couldn’t prepare them for.

Community rebuilding begins with honoring shared memories—the lines for government cheese, the final shifts—transforming collective hardship into a foundation for renewed identity and belonging.

From Production Lines to Poverty: The Socioeconomic Aftermath

Devastation cascades through communities when production lines fall silent, leaving behind more than vacant factory floors.

You’ve seen towns where manufacturing employment plummeted from 38% to under 9%, creating socioeconomic disparities that persist decades later. What once sustained families transformed into generational poverty.

In your community’s struggle, you’ll recognize:

- The vicious cycle of population exodus, shrinking tax bases, and deteriorating public services

- Family breakdown accompanying the collapse of social capital and community resilience

- The stark reality that service sector growth failed to absorb displaced workers at comparable wages

Your hometown’s story isn’t merely economic disruption but structural impoverishment.

The physical decay of buildings mirrors the institutional breakdown within – evidenced through rising rates of addiction, depression, and lost trust in once-respected institutions. These hardships are especially devastating in monoindustrial communities where economic survival depended entirely on a single employer. This pattern follows the broader trend where manufacturing employment share fell from 28% to 18% across advanced economies between 1970 and 1994.

Generational Ripple Effects: How Manufacturing Decline Reshapes Family Futures

The generational consequences of manufacturing’s collapse reach far beyond immediate job losses, creating ripple effects that reshape children’s futures and alter family trajectories across decades.

When your parents lose factory jobs, your own path narrows—research shows you’ll face lower college attendance rates and decreased adult earnings. Educational disparities widen in communities with high racial segregation, where manufacturing decline hits hardest. With nearly one-quarter of the manufacturing workforce age 55 or older, younger generations face a shrinking pathway to industrial careers.

Though dropout rates actually decrease as young people seek alternatives to vanishing factory work, the quality of educational outcomes suffers.

Employment challenges multiply across generations. You’ll witness your community aging as young workers flee, while those who stay confront diminished opportunities. A shocking 4.6 percentage point drop in employment rates has particularly affected prime-age men since 2000, leaving families with fewer breadwinners and role models.

The skilled hands that built America’s middle class now struggle with higher mortality rates, chronic illness, and reduced mobility—a legacy of economic disruption that continues reshaping family futures decades after factory gates close.

Forgotten Expertise: Preserving the Cultural Heritage of Industrial Craftsmanship

How do you preserve the soul of a community after its economic heartbeat stops? When factories close, they take with them not just jobs but generations of specialized knowledge—the intricate metalworking techniques, textile patterns, and machinery skills that defined your town’s identity.

Preserving this industrial craftsmanship requires immediate action:

- Create extensive skill documentation through digital archives and 3D scanning before aging artisans take their expertise to the grave.

- Establish cross-generational apprenticeships that connect youth with masters in hands-on workshops.

- Build sustainable artisan networks that combine traditional methods with modern technology for economic viability.

These preservation efforts represent a commitment to resource management and ecological sustainability, ensuring industrial traditions evolve rather than disappear.

Embracing cultural narratives through materials and design can help communities maintain their distinctive identity even as manufacturing landscapes change.

You’re not just saving techniques; you’re protecting the cultural DNA that makes your community unique.

Without deliberate preservation, these industrial crafts—and the pride they instill—will vanish forever.

Frequently Asked Questions

How Do Former Manufacturing Workers Adapt to the Digital Economy?

You’ll need to develop digital skills through training programs and seek remote employment opportunities. In your community’s factories, where generations worked, new pathways now emerge from industrial ruins toward technological freedom.

What Specific Mental Health Impacts Emerged in Post-Industrial Communities?

You’ll find depression prevalence soared in your once-proud towns, where deindustrialization shattered community resilience. Anxiety, emotional instability, and diminished life satisfaction have taken root in the very soil of your heritage.

How Did Religious Institutions Respond to Manufacturing Community Collapse?

Like lighthouses in economic storms, you’ll find religious institutions pivoting toward faith-based outreach when factories closed. They offered community support through disaster relief, established resource networks, and preserved local heritage amid industrial collapse.

Which Manufacturing Communities Successfully Reinvented Their Economic Identities?

You’ll find Akron, Pittsburgh, Chicago, and St. Louis successfully reinvented themselves through economic diversification strategies and community resilience initiatives, transforming from traditional manufacturing to polymer science, sustainability, green infrastructure, and innovation hubs respectively.

How Did Manufacturing Decline Affect Voting Patterns in Affected Regions?

When your industrial backbone weakened, your community split along racial lines—white voters swung Republican while Black voters remained Democratic. You’ve witnessed deepening political polarization shaped by voting demographics tied to your hometown’s manufacturing heritage.

References

- https://www.visualcapitalist.com/the-decline-of-u-s-manufacturing-by-sector/

- https://fiveable.me/history-of-american-business/unit-14/decline-traditional-manufacturing-industries/study-guide/Xz71flaSf68CfK2X

- https://www.journals.uchicago.edu/doi/full/10.1086/700896

- https://www.clevelandfed.org/publications/economic-commentary/2017/ec-201714-whats-gone-wrong-and-right-in-the-industrial-heartland

- https://www.epi.org/publication/botched-policy-responses-to-globalization/

- http://www.ers.usda.gov/amber-waves/2017/october/rural-manufacturing-survival-and-its-role-in-the-rural-economy

- https://www.bls.gov/opub/btn/volume-9/forty-years-of-falling-manufacturing-employment.htm

- https://news.mit.edu/2012/manufacturing-overseas-competition-0224

- https://www.cato.org/publications/reality-american-deindustrialization

- https://www.deloitte.com/us/en/insights/industry/manufacturing-industrial-products/manufacturing-industry-outlook.html