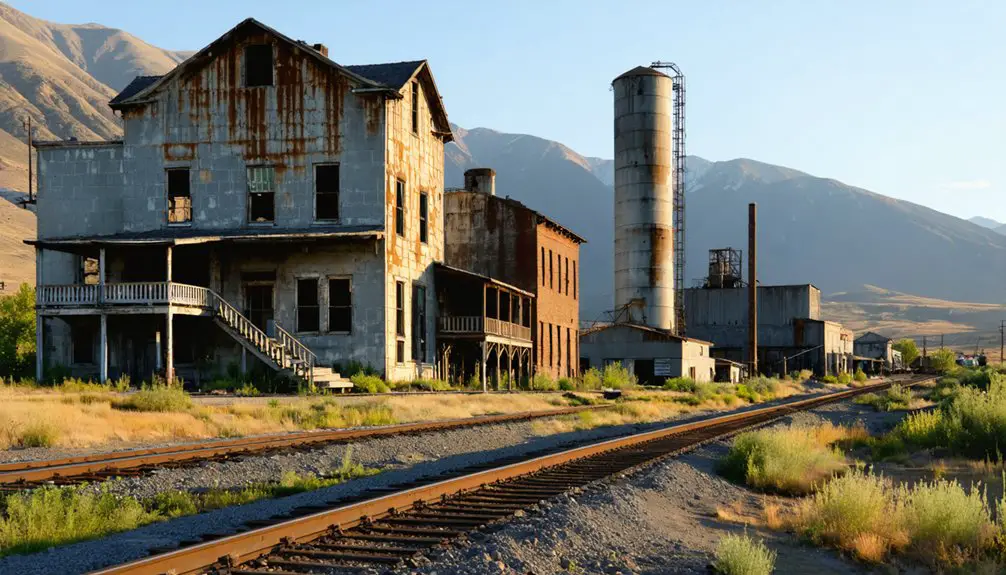

You’ll find Trident nestled at the convergence of Montana’s Gallatin, Madison, and Jefferson rivers – a once-thriving cement company town established in 1908. The Red Devil Portland Cement operation employed 200 workers at its peak, with daily rail shipments reaching 30 cars by the 1910s. Today, this ghost town’s preserved depot and industrial ruins tell the story of early 20th-century innovation, immigrant labor, and the rise and fall of American manufacturing towns.

Key Takeaways

- Trident, Montana was established in the early 1900s as a company town centered around cement production and railroad operations.

- The town experienced significant decline between 1920-1940, with workforce dropping from 200 workers and families to much smaller numbers.

- Original town infrastructure included worker cottages, a hotel, theater, store, and school, most of which no longer serve their initial purpose.

- The Northern Pacific Railroad depot, relocated in 2011, remains a preserved landmark of Trident’s industrial past.

- While no longer a bustling company town, modern cement operations continue at Trident, preventing it from becoming completely abandoned.

The Birth of a Company Town

When abundant limestone deposits met the expanding Northern Pacific Railroad in early 1900s Montana, the stage was set for Trident’s emergence as a company town.

Originally planned to be “Three Forks,” the name was already taken, so planners chose “Trident” to symbolize the three rivers – Gallatin, Madison, and Jefferson – forming the Missouri River like a three-pronged spear.

Like the trident of Neptune, three mighty rivers converge at this aptly named Montana town, forging the Missouri’s headwaters.

You’ll find the town’s strategic layout reflected its industrial purpose.

East of the railroad tracks stood the cement plant’s infrastructure – kilns, mills, and warehouses.

On the riverside, about 40 company-owned cottages housed workers and their families, alongside a hotel, theater, store, and school.

A makeshift shanty town sprouted north of the plant, first hosting Japanese laborers before becoming home to European immigrants seeking opportunity in this burgeoning industrial outpost.

The Red Devil Portland Cement Legacy

You’ll find Red Devil Portland Cement‘s first momentous shipment left the Trident plant on June 10, 1910, with 424 burlap sacks bound for Missoula Mercantile Company.

The plant’s production quickly ramped up to an impressive six to eight railcars daily, eventually reaching peak shipments of 25 to 30 cars per day during the height of operations.

The company’s success brought steady employment to the region, establishing Trident as an essential industrial hub with worker housing and infrastructure that supported the growing cement manufacturing workforce.

Industrial Production Milestones

The Red Devil Portland Cement legacy began with a landmark shipment on June 10, 1910, as Three Forks Portland Cement Company dispatched 424 sacks to the Missoula Mercantile Company.

You’ll find this initial cement shipment quickly expanded to 6-8 rail cars daily, eventually reaching an impressive 25-30 cars. The plant’s strategic location near three rivers and the Northern Pacific Railroad fueled its rapid growth, enabling it to supply cement for major infrastructure projects across the region.

- Trident’s cement helped build iconic structures like Holter Dam and Morony Dam, showcasing American industrial independence.

- Daily production volumes soared as the plant reached full capacity within its first eight years.

- The construction of a dedicated railroad depot in 1911 marked Trident’s emergence as an essential industrial hub.

Labor Force Demographics

Beyond the impressive production milestones, Trident’s workforce painted a rich portrait of early 20th-century industrial demographics.

You’ll find notable examples of workforce integration through the presence of women like Gail Winnifred Clark and Edna Pearl Knight, who challenged traditional gender roles in manufacturing.

The plant’s labor force spanned various skill levels, from chemists like A.D. Burkett to workers handling the iconic Red Devil cement bags.

While European-American names dominated the employee records, the workforce actively participated in community life, attending school Christmas programs and local events.

The plant’s diverse labor structure included both technical expertise and manual skills, reflecting the complex nature of cement manufacturing during this era.

Workers’ deep community ties helped shape Trident’s industrial identity.

Railroad’s Role in Trident’s Development

Spurred by Northern Pacific Railroad‘s strategic presence, Trident’s establishment and rapid growth stemmed directly from the rail line’s critical role in cement production and distribution. The railroad significance transformed a remote location into a bustling industrial hub, with daily railcar traffic surging from 6-8 to 25-30 cars by the early 1910s.

You’ll find the transportation efficiency revolutionized cement distribution across the region, prompting Northern Pacific to authorize a dedicated depot in 1911.

- The uniquely designed depot, combining wood structure with brick façade, served as the lifeline for managing raw materials and finished products.

- Rail operations catalyzed the development of essential community infrastructure, including housing, stores, and schools.

- The depot’s 2011 relocation to Three Forks preserves the lasting legacy of railroad’s impact on Trident’s industrial heritage.

Immigrant Workers and Cultural Diversity

These immigrant contributions extended beyond manual labor. While many worked in mining and manufacturing, others became entrepreneurs, generating substantial revenue across Montana.

Despite facing discrimination and legal challenges like the Chinese Exclusion Act, immigrant communities preserved their cultural heritage through shared traditions, language, and social institutions.

Their resilience transformed Trident into a multicultural industrial village where ethnic neighborhoods, schools, and social venues fostered cultural preservation amid challenging conditions.

Daily Life in a Montana Industrial Village

Life in Trident’s industrial village centered around the rhythms of factory work, where rows of company-built houses stretched along railroad lines and factory perimeters.

You’d find daily routines shaped by factory shifts, with families rising early to prepare for long workdays. Community gatherings in ethnic halls and churches provided relief from the demanding industrial schedule, while children split their time between local schooling and helping with household duties.

- When work accidents occurred, you’d rely on neighbors and extended family networks for support and care.

- You’d supplement factory wages through small-scale farming and seasonal agricultural work.

- Your social connections often formed along ethnic lines, creating tight-knit cultural groups that preserved traditional customs.

Beyond the factory’s demands, daily life wove together work, cultural traditions, and the harsh realities of industrial labor in early Montana.

The Rise and Fall of Cement Production

You’ll find that Trident’s cement production reached its zenith during the early 1920s, with up to 30 railcars of product leaving the facility daily and a workforce of 200 employees operating the plant.

The company town’s prosperity reflected the broader American cement boom, as nationwide production soared from 335,000 barrels in 1890 to 176 million barrels by 1928.

Between 1920 and 1940, however, the plant consistently operated below capacity despite regional demand, signaling the economic challenges that would eventually lead to the town’s decline.

Peak Production Years

From its first cement shipment in 1910, Trident’s production rapidly accelerated to meet Montana’s growing infrastructure demands.

You’ll find that peak shipping reached an impressive 25-30 railcars daily, prompting Northern Pacific Railroad to build a specialized depot by 1911. The economic impact rippled through the region as Trident’s cement fueled the construction boom of the early 20th century.

- The plant’s 200-person workforce transformed a remote location into a bustling industrial hub

- Rail connections opened crucial supply lines to growing Western markets

- Production aligned perfectly with America’s infrastructure explosion, when national cement output jumped from 335,000 to 176 million barrels

This golden age of cement manufacturing positioned Trident as a key player in Montana’s industrial development, capitalizing on rich limestone deposits and strategic rail access.

Labor and Economic Downturn

While Trident’s peak years showcased remarkable growth, the cement industry’s volatility soon tested the town’s resilience. The labor market, which once supported 200 workers and their families, began to contract as production levels fell below capacity between 1920 and 1940.

You’d have seen the impact of this decline in the daily rail shipments, which dropped from their impressive peak of 25-30 railcars per day.

The town’s economic resilience faced mounting challenges during the Great Depression, as national cement production surged while local demand plummeted.

Price competition from emerging regional plants, coupled with skilled labor shortages, strained Trident’s operational viability.

Without capital for modernization and faced with declining revenues, the plant’s workforce gradually dispersed, leaving behind a community that had once thrived on cement production.

Preserving Trident’s Industrial Heritage

Despite the decline of Trident’s once-bustling industrial community, preservation efforts have helped safeguard key elements of its heritage for future generations.

You’ll find the centerpiece of heritage preservation at the Railroad and Trident Heritage Center, where community engagement rescued and relocated the unique Trident Depot in 2011. The center, situated in John Q. Adams Milwaukee Railroad Park, now connects visitors to the region’s industrial past through carefully curated artifacts and displays.

The historic Trident Depot lives on at the Heritage Center, preserving railroad history through rescued artifacts and community dedication.

- The depot’s distinctive architecture stands as a symbol of Northern Pacific Railroad’s influence on Montana’s development

- Surviving industrial artifacts, from pump house remains to cottage remnants, tell the story of a 3,000-strong company town

- Modern cement operations continue Trident’s industrial legacy while preservation efforts protect its cultural heritage through adaptive reuse and heritage centers

From Bustling Industry to Ghost Town

The establishment of Trident in 1908 marked the beginning of a remarkable industrial saga that would span over a century.

Much like the booming mining operations that drove Montana’s early economy when the Anaconda Copper Mining opened in 1884, Trident became a vital industrial center. During the peak mining era, workers in Montana’s mining towns earned about $3.50 per day.

You’ll find the community’s resilience reflected in how it adapted to the cement industry’s demands, shipping up to 30 rail cars daily during peak operations.

Montana’s Mining Town Connections

Since Montana’s mineral wealth first drew prospectors westward in 1852, a vast network of mining towns emerged across the state’s rugged landscape, particularly in its southwestern region.

Montana’s 1852 mineral discoveries sparked a sprawling web of mining settlements that forever changed the state’s southwestern frontier.

You’ll find historical significance in the connections between these settlements, from Bannack’s early gold strikes to Butte’s copper empire. The interest in copper surged dramatically around 1880, marking a transformative period for Montana’s mining industry. The development of railroads in the 1880s strengthened these mining town connections, creating essential transportation links that enabled communities to flourish and share resources. The establishment of the Anaconda Copper Company marked a turning point in centralizing and industrializing the region’s mining operations.

- The progression from Bannack to Virginia City to Helena shows how mining success shifted across the region.

- Railroad networks transformed isolated mining camps into interconnected economic powerhouses.

- Mining towns’ shared labor movements and union activism created lasting social bonds between communities.

Frequently Asked Questions

Are Any Original Buildings From Trident Still Standing Today?

You’ll find only two remnants of Trident’s original architecture: the pump house still stands at its original site, while the historic depot’s been preserved through relocation to nearby Three Forks.

What Happened to the Families Who Lived in Trident?

Like scattered seeds in the wind, Trident families dispersed across Montana when the cement plant closed, moving to Three Forks and larger cities for work, leaving their company-owned homes behind.

Can Visitors Explore the Former Cement Plant Site?

You can’t safely or legally explore the former cement plant site. There’s no public access or established exploration guidelines, and the deteriorating industrial structures remain off-limits due to safety concerns.

What Was the Maximum Population of Trident During Its Peak?

While Trident’s history whispers through ghost town artifacts today, you’ll find records suggesting the population peaked at around 300-400 residents during the 1950s when the cement plant employed its largest workforce.

Were There Any Major Accidents or Disasters at the Cement Plant?

While typical industrial accidents occurred, you won’t find records of major disasters at Trident’s cement plant. In fact, they achieved 3,000 accident-free days around 1982, showing strong safety practices.

References

- https://www.garnetghosttown.org/history.php

- https://www.railstotrails.org/trailblog/trident-depot-saved-by-community-in-three-forks-encapsulates-the-regions-rich-history/

- https://southwestmt.com/blog/ghost-town-terror-gunslinger-gulch/

- http://www.tfhistory.org/history Trident 01.html

- https://www.historynet.com/copper-city-montana-ghost-town/

- https://www.hcn.org/articles/the-montana-gap-three-forks-montana-wants-to-grow-but-not-too-quickly-can-it-stay-in-control/

- https://threeforksmontana.us/our-history

- https://www.hmdb.org/m.asp?m=126996

- https://montanahistoriclandscape.com/2016/02/01/montanas-three-forks-part-2/

- https://utahrails.net/industries/cement.php