American manufacturing towns declined due to multiple forces converging since the 1990s. You’ve witnessed automation replacing 87% of manufacturing jobs, while offshoring (particularly after China joined the WTO in 2001) eliminated 3.7 million positions. These technological and global trade shifts transformed the U.S. economy from factory-focused to service-oriented, creating ripple effects that devastated local economies. The impact extends far beyond lost jobs into community infrastructure and demographic patterns.

Key Takeaways

- Automation and robotics replaced human labor, with technology driving 87% of manufacturing job losses between 2000-2010.

- Globalization and offshoring moved production to countries with cheaper labor, resulting in nearly 70,000 factory closures across America.

- China’s entry into the WTO in 2001 dramatically increased imports and displaced approximately 1.5-2 million U.S. manufacturing jobs.

- Economic shifts transformed the workforce from manufacturing to service industries, reducing manufacturing’s GDP contribution from 20% to 10%.

- Factory closures created ripple effects including tax base erosion, population decline, and reduced spending power in local economies.

The Impact of Automation and Technology on Factory Employment

While manufacturing output has steadily increased over the past three decades, employment in the sector has paradoxically declined due to automation’s transformative impact.

You’ve witnessed this dramatic shift where machines, not globalization, drove 87% of manufacturing job losses between 2000-2010.

The automation impact is undeniable—US manufacturing output grew by 72% from 1990-2016 while employment fell by 30.7%.

Robots and AI now handle repetitive tasks that once employed thousands. This aging workforce challenge has compounded the industry’s talent shortage as experienced workers retire without adequate knowledge transfer to younger generations.

The technological revolution is projected to displace another 1.6-3.2 million jobs in coming decades.

Industrial robots have disproportionately impacted certain demographic groups, with non-White workers experiencing a 4.5 percentage point reduction in employment compared to 1.8 points for White workers.

Workforce adaptation remains challenging as manufacturing evolves from manual labor toward technical oversight roles.

The skills that secured factory jobs yesterday won’t suffice tomorrow, creating painful changes in communities built around traditional manufacturing employment.

Global Competition and the Offshoring of Production

Although automation considerably transformed manufacturing, global competition and offshoring have dealt an equally devastating blow to America’s industrial towns. The statistics are sobering: over 5 million manufacturing jobs disappeared between 1998 and 2021, with 3.7 million jobs lost to Chinese imports alone.

You’ve witnessed the restructuring of global supply networks as companies relocated factories to Vietnam, Mexico, and Indonesia seeking cheaper labor and fewer regulations. This wasn’t inevitable—mismanaged trade policies, currency manipulation, and persistent U.S. dollar overvaluation accelerated the exodus. Manufacturing employment decreased by 17 percent from 2002 to 2022, while the overall U.S. economy experienced job growth of more than 14%.

Towns once thriving with factory work saw sharp employment declines as production moved offshore. The massive loss of nearly 70,000 factories across America further confirms the devastating impact of globalization. The net effect? Approximately 3.5 million manufacturing jobs vanished between 1991 and 2019, leaving regional inequalities and struggling communities in their wake—clear evidence that offshoring, not just productivity gains, gutted America’s industrial base.

China’s WTO Entry and the Reshaping of American Manufacturing

When China joined the World Trade Organization in 2001, it triggered a seismic shift in American manufacturing that reshaped entire industries and communities.

The aftermath saw Chinese manufacturing exports to the U.S. surge 290% in just six years, driving U.S. manufacturing prices down by 7.6%.

China’s productivity skyrocketed, with total factor productivity growing 10% annually as reduced tariffs and policy certainty transformed its export capacity.

This contributed to the loss of 1.5 to 2 million U.S. manufacturing jobs, concentrated in factory towns.

Despite these challenges, U.S. competitiveness in manufacturing output continued its upward trajectory.

The job losses stemmed primarily from technological advances and voluntary workforce changes, rather than productivity declines.

Academic research indicates that 93.7% of Americans lived in areas experiencing neutral or positive effects from trade with China.

However, the growing trade deficit with China ultimately shifted the composition of American manufacturing toward higher-skilled production.

American consumers benefited significantly, with lower prices resulting in substantial savings of $340 billion in the U.S. manufacturing sector by 2014.

From Factory Floor to Service Economy: Changing Employment Patterns

As America’s manufacturing sector contracted from 32% of the workforce in 1960 to below 9% today, a fundamental economic transformation has reshaped the nation’s employment landscape.

This dramatic labor reallocation has shifted more than 80% of U.S. workers into service industries.

You’re witnessing high-skilled services dominating the economy, accounting for 67% of employment and 75% of earnings. Healthcare and education have more than doubled their employment share to 21%, while manual labor functions declined from 30% to just 16%. The most recent data shows continuing job losses, with 42,000 manufacturing jobs disappearing since April 2025 alone.

Unlike other developed nations that maintained manufacturing at 15-25% of GDP, America’s manufacturing contribution fell from over 20% to merely 10%.

The service sector’s rise reflects both technological efficiency in goods production and shifting consumer priorities, fundamentally altering the economic foundation of many American communities. This decline represents a significant shift from the post-World War II period when manufacturing provided well-paying opportunities for workers without college degrees.

The Ripple Effects of Plant Closures on Community Prosperity

You’ll find that plant closures devastate far beyond the factory gates, with research showing up to 16.5 indirect jobs lost for every $1 million drop in manufacturing demand.

This economic cascade transforms entire communities as displaced workers either relocate or exit the labor force permanently, leaving behind shrinking tax bases and declining property values.

The demographic aftermath is particularly severe in vulnerable rural areas, where poverty rates increase, population decreases, and the community’s ability to attract new investment diminishes substantially. These communities face prolonged financial strain, struggling to maintain essential public services like education, police departments, and infrastructure. Communities with higher isolation factors, measured by travel time to cities over 50,000 in population, typically experience more severe and persistent economic downturns.

Vanishing Economic Ecosystems

Manufacturing plant closures trigger far more devastating consequences than their immediate job losses suggest. When a facility shuts down, you’re witnessing the collapse of entire economic ecosystems, not just the elimination of specific jobs.

Every 100 manufacturing positions lost creates approximately 744 additional job casualties throughout the community. This multiplier effect devastates local businesses as spending power evaporates. The impact spreads rapidly—upstream suppliers lose orders, downstream industries lose inputs, and service sectors suffer from reduced consumer demand.

Community resilience weakens as tax revenues plummet, limiting public services exactly when they’re most needed. The destruction is particularly pronounced in manufacturing because of its strong economic linkages.

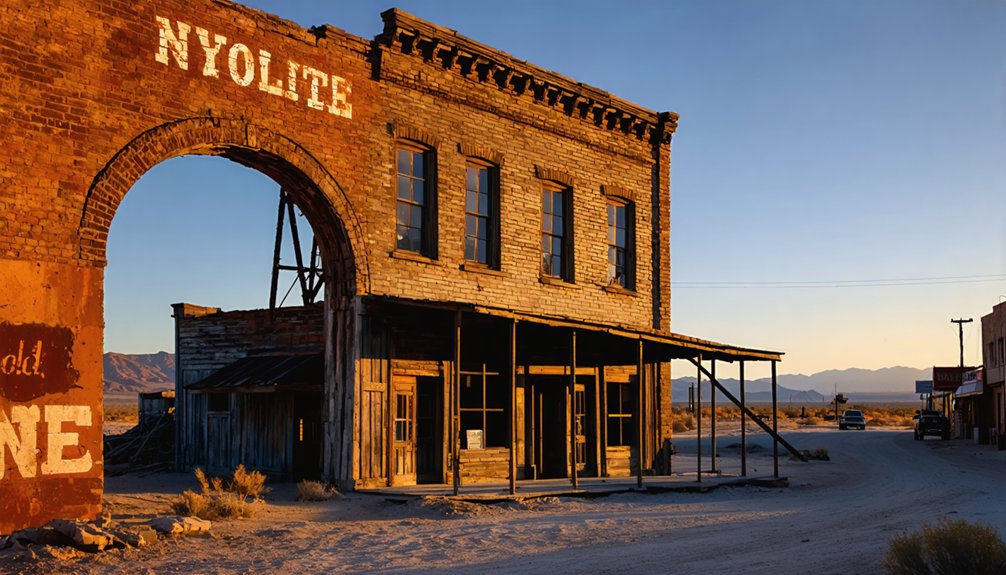

The factory closure you see today becomes tomorrow’s vacant storefronts, declining school enrollments, and deteriorating infrastructure—transforming once-vibrant towns into shells of their former prosperity.

Demographic Spiral Down

When a factory shutters its doors, it initiates a demographic death spiral that extends far beyond lost paychecks.

You’ll witness population migration as younger workers flee to urban centers with better opportunities, leaving behind aging communities ill-equipped to attract new investment.

This exodus creates economic stagnation that compounds with each closure. In Lordstown, Ohio, GM’s departure eliminated 8,000 jobs, accelerating community shrinkage.

Similarly, rural areas like Evart, Michigan and Canton, North Carolina saw critical job losses that decimated their tax bases.

The aftermath is predictable: property values plummet, housing vacancies rise, and poverty rates climb.

Communities shift from well-paid manufacturing to lower-wage service jobs, reducing overall prosperity.

Your community’s social fabric tears as schools, police, and other essential services face budget shortfalls.

Regional Disparities in Manufacturing Recovery and Decline

You’ll notice a striking geographic divergence in manufacturing recovery, with Sun Belt and Mountain West regions gaining jobs while coastal metros and traditional manufacturing hubs suffer persistent losses.

This east-west divide has accelerated post-pandemic, as Los Angeles shed 40,000 manufacturing jobs while smaller communities in states like Texas, Arizona, and Nevada attract new factories and expansions.

Small manufacturing towns in growth regions now routinely outperform major cities in job creation, highlighting how production is shifting away from high-cost coastal areas toward more affordable, business-friendly environments in the South and West.

East-West Divide Widens

The striking transformation of America’s manufacturing landscape reveals a widening East-West divide that has reshaped the nation’s economic geography over the past six decades.

You’re witnessing industrial migration from traditional hubs in New England and the Mid-Atlantic (where manufacturing employment plummeted from around 40% to below-average levels) toward central and southern regions.

This economic polarization intensified as Texas and Florida added 164,000 manufacturing jobs since 2017, while Northeast areas contracted.

The Mountain West and Upper Midwest experienced construction booms while once-dominant manufacturing centers declined.

Manufacturing hasn’t disappeared—it’s relocated and evolved.

Although productivity improvements drove job losses more than trade alone, the regional impacts weren’t equal.

The East’s manufacturing decline continues while the West and South capitalize on lower costs and emerging industry clusters.

Small Towns Outperforming Cities

Contrary to decades-long trends of urban manufacturing dominance, small urban counties have emerged as unexpected powerhouses in America’s industrial landscape, generating 61% of all new manufacturing jobs since 2019—a dramatic surge from their pre-pandemic share of less than 20%.

These small town advantages include affordable land combined with access to sizeable labor markets, creating the perfect middle ground for manufacturers seeking efficiency.

Meanwhile, urban decline continues in traditional manufacturing hubs where costs have skyrocketed. McLean County, Illinois exemplifies this shift, gaining 7,100 manufacturing jobs through Rivian’s expansion.

You’ll find that left-behind rural counties are now outpacing their previous performance, adding four times more jobs between 2020-2023 than in the prior three years.

Manufacturing remains especially critical in these areas, representing 21% of rural nonfarm earnings versus just 11% in urban areas.

Frequently Asked Questions

How Did Unionization Affect Manufacturing Town Resilience?

Like Atlantis before the flood, strong union strategies created safety nets through labor negotiations. You’ll find unionization protected wages, benefits, and community services until its decline left towns vulnerable to economic shocks.

What Role Did Environmental Regulations Play in Factory Closures?

Environmental regulations created significant regulatory impact through added compliance costs. You’ll find pollution controls forced closures when firms couldn’t absorb expenses, pushing many to relocate where restrictions were less burdensome.

How Did Education Systems Adapt to Changing Manufacturing Needs?

As manufacturing’s gears shifted, you’ve watched education systems retool themselves, implementing curriculum changes focused on technical skills and expanding vocational training to prepare your workforce for automation’s relentless advance toward higher skill requirements.

Which Manufacturing Industries Proved Most Resistant to Decline?

You’ll find durable goods, particularly transportation equipment with automotive innovation, have resisted decline most effectively, alongside plastics/rubber products and energy manufacturing. Even textiles survived through adaptation to specialized markets.

What Demographic Shifts Occurred in Manufacturing Towns Post-Decline?

You’ve witnessed massive out-migration of younger workers, aging populations, racial segregation patterns, and selective in-migration driving economic diversification in previously declining areas, reshaping communities and challenging traditional social structures.

References

- https://www.ien.com/operations/news/22879822/why-the-rural-south-is-in-economic-crisis-because-of-manufacturing

- https://prosperousamerica.org/job-loss-by-metro-area-shows-devastation-from-china-shock/

- https://www.nber.org/digest/202404/global-evidence-decline-and-recovery-rust-belt-cities

- https://ysu.edu/center-working-class-studies/social-costs-deindustrialization

- https://www.governing.com/archive/gov-legacy-city-struggling-cities.html

- https://www.usda.gov/about-usda/news/blog/manufacturing-relatively-more-important-rural-economy-urban-economy

- https://eig.org/manufacturing-rebound/

- https://www.cato.org/blog/economic-mobility-not-manufacturing-decline-real-rust-belt-story

- https://www.coopercenter.org/research/young-adults-fuel-revival-small-towns-rural-areas

- https://ssti.org/blog/useful-stats-where-us-manufacturing-county-level-look-subsector-specific-data