You’ll find over 1.2 million hectares of abandoned industrial sites worldwide, with 450,000 brownfield locations in the U.S. alone. These silent monuments harbor complex chemical contamination, defunct machinery, and architectural remnants from manufacturing’s golden age. From the American Rust Belt to China’s Northeast corridor, these wastelands face challenges including $17 billion in lost investments and 21,000 eliminated jobs in 2025. The story of their transformation reveals both environmental threats and promising opportunities for revitalization.

Key Takeaways

- Over 1.2 million hectares of former industrial land lie dormant worldwide, including 450,000 brownfield sites in the United States alone.

- Abandoned infrastructure includes factories, grain elevators, fire stations, and underground networks like Cincinnati’s 11-mile unused subway system.

- Complex chemical contamination threatens groundwater and soil, with cleanup costs ranging from $50 to $100,000 per square meter.

- Original industrial machinery, rail infrastructure, and heavy power connections remain disconnected but offer potential for adaptive reuse.

- Physical remnants create opportunities for architectural preservation, data centers, advanced manufacturing facilities, and sustainable development projects.

The Scale of Industrial Abandonment in 2025

While the global shift toward service economies continues, the scale of industrial abandonment has reached unprecedented levels in 2025, with over 1.2 million hectares of former industrial land lying dormant worldwide.

You’ll find the starkest examples of industrial decline in the United States, where 450,000 brownfield sites dot the landscape, and the European Union, which grapples with 250,000 defunct industrial zones.

China’s rust belt regions showcase this pattern of urban decay, with over 30,000 abandoned industrial areas concentrated in the Northeast. Recent studies reveal that complicated checkout processes are causing similar economic losses in digital commerce.

The situation is particularly telling in G20 nations, where satellite data reveals 18% of former heavy-industry zones remain completely vacant. Similar to shopping cart abandonment rates hitting 69.99% in digital retail, these industrial wastelands represent massive economic losses.

These silent monuments to deindustrialization span continents, reflecting a profound transformation in global economic patterns.

Economic Forces Behind Project Cancellations

The staggering scale of industrial abandonment connects directly to widespread project cancellations driven by complex economic forces.

You’ll find that market dynamics have created a perfect storm where $17 billion in decarbonization investments vanished due to regulatory uncertainty and weak demand for low-carbon products.

Investment barriers, including fluctuating tax policies and unclear federal guidance, have paralyzed decision-making across clean energy sectors. Without adequate policy guidance, manufacturers struggle to secure financial stability and proceed with planned developments. The industry faces devastating losses with 21,000 jobs eliminated through renewable energy project closures this year.

Regulatory chaos and policy inconsistencies continue blocking billions in clean energy capital, leaving vital climate projects frozen in bureaucratic limbo.

- Empty battery gigafactories stand as monuments to shifting corporate strategies and hesitant buyers unwilling to commit to premium pricing.

- Abandoned hydrogen plant construction sites reflect the harsh reality of first-mover risks and uncertain market demand.

- Partially built clean energy facilities showcase how tariff escalations and permit delays have devastated project economics.

Geographic Distribution of Deserted Sites

Mapping abandoned industrial sites across America reveals distinct geographic clusters that tell a story of economic transformation and resource depletion.

You’ll find over 275,000 abandoned mines concentrated in historic extraction regions, with the National Mine Map Repository providing vital geospatial analysis of these sites.

The Rust Belt region, stretching from the Midwest to Northeast, shows the highest density of deserted industrial complexes and ghost towns.

When you examine the historical context, you’ll see how these clusters align with specific economic eras – from California’s Sierra Nevada mining boom to Pennsylvania’s coal heritage.

Users exploring these sites should seek permission first before accessing any private property to document these industrial remnants.

The geographic patterns aren’t random; they trace the rise and fall of America’s industrial might, following abandoned railroad corridors and manufacturing centers that once drove regional economies.

Job Losses and Community Impact

You’ll witness the stark reality of America’s industrial decline through the staggering loss of 78,000 manufacturing jobs in 2025 alone, accompanied by widespread plant closures and a contracting Manufacturing PMI of 48.7%.

Your local communities face devastating ripple effects as these job losses trigger secondary unemployment in retail and services, while depleting municipal tax bases that fund essential public services.

When you examine affected regions more closely, you’ll find a troubling pattern of long-term disinvestment where manufacturing job losses have initiated a destructive cycle of reduced consumer spending, business closures, and population exodus.

The automotive sector has been particularly hard hit, with 7,300 jobs eliminated in August, deepening the economic struggles of traditional manufacturing hubs.

The warehousing industry has seen unprecedented changes, with 378 percent more layoffs compared to the previous year, intensifying the economic challenges in distribution-heavy regions.

Lost Manufacturing Dreams

Manufacturing’s latest downward spiral has dealt a crushing blow to American workers, with Department of Labor statistics revealing 78,000 lost jobs between January and August 2025 alone.

You’re witnessing lost opportunities cascade through communities as once-thriving factories fall silent, with durable goods and fabricated metals sectors hit particularly hard.

- Empty parking lots where thousands of cars once filled morning shifts

- Dormant assembly lines that previously supported generations of families

- Locked factory gates where “Help Wanted” signs have been replaced by “For Sale” notices

The shattered hopes extend beyond raw numbers – 313,000 job separations in August 2025 represent real families facing uncertain futures.

Even sectors offering six-figure salaries, like Ford’s mechanic positions, can’t bridge the growing skills gap that’s accelerating manufacturing’s decline.

This marks an eighth consecutive month of manufacturing job contraction, signaling a persistent downward trend in the sector.

Nearly 2 million unfilled jobs are projected by 2030 as manufacturers struggle to find qualified workers amid increasing automation.

Workforce Exodus Impact

As veteran workers retire en masse from America’s manufacturing sector, a demographic time bomb threatens the industry’s stability, with nearly 25% of the workforce now aged 55 or older.

You’re witnessing a critical workforce retention crisis that’s draining decades of accumulated expertise, with poor knowledge transfer costing businesses $47 million annually.

The exodus is devastating local communities where manufacturing once thrived. You’ll find shrinking tax bases, declining public services, and eroding economic resilience in these areas. Projections indicate 1.9 million positions will remain unfilled by 2033, further intensifying the economic strain on these communities.

Labor shortages persist, with 313,000 unfilled positions in durable goods manufacturing alone. Without proper industrial training and skill development initiatives, the sector faces a projected 2.1 million worker deficit by 2030.

This workforce drain weakens community engagement and threatens the cultural fabric of industrial towns across America.

Infrastructure Left Behind

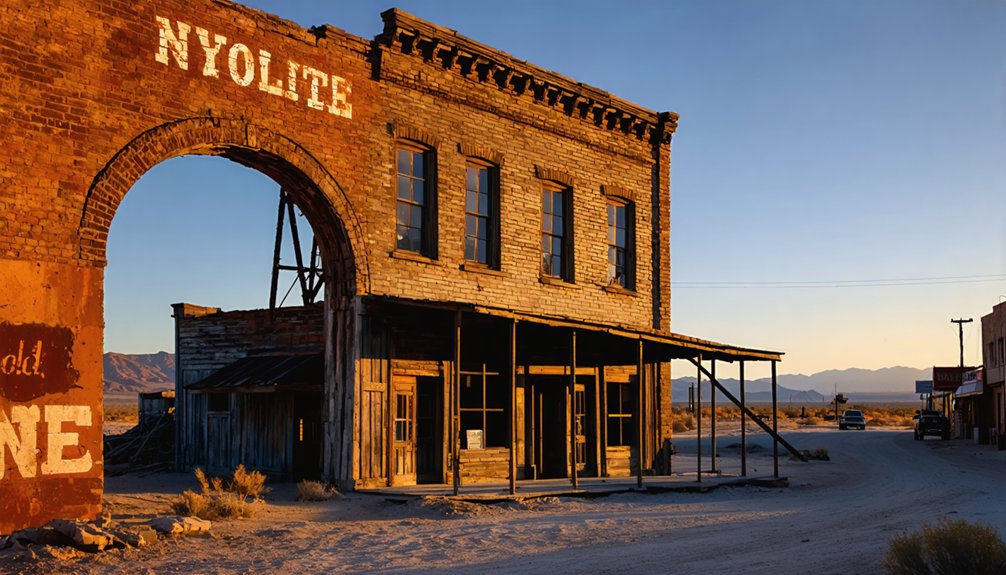

While industrial operations have long since departed, the physical remnants of manufacturing’s golden age persist throughout today’s silent industrial landscapes.

You’ll find abandoned infrastructure that tells stories of America’s industrial might – from crumbling fire stations and factories to sentinel-like grain elevators standing watch over empty shorelines. The architectural preservation of these spaces presents unique opportunities for urban exploration and innovative design through adaptive reuse.

- Subterranean networks of unused subway tunnels stretch beneath cities, with Cincinnati’s 11-mile system serving as a demonstration of unrealized ambitions.

- Original rail infrastructure, loading docks, and industrial machinery remain frozen in time, disconnected from modern transportation grids.

- Foundations and utility systems endure even as structures above ground decay, providing frameworks for site revitalization and community engagement.

Environmental Legacy and Concerns

You’ll find these abandoned industrial sites harboring complex chemical cocktails of heavy metals, VOCs, and persistent organic pollutants that continue seeping into groundwater and soil decades after operations cease.

The astronomical costs of proper environmental remediation – often running into millions per acre – leave many sites in perpetual limbo as neither developers nor local governments can shoulder the financial burden.

Continuous monitoring reveals how contamination plumes expand outward from these sites, threatening nearby communities’ drinking water supplies and ecosystem health, yet funding for tracking these threats remains chronically insufficient.

Contamination Risks Linger On

Although industrial sites may appear dormant, their environmental threats remain active through multiple pathways of contamination.

You’ll find toxic legacies lurking beneath the surface, where thawing permafrost threatens to mobilize over 4,600 contaminated sites by century’s end. These contamination pathways aren’t static – they’re evolving with our changing climate.

- Floodwaters breach containment systems at aging industrial sites, spreading heavy metals and volatile compounds across neighborhoods where 200,000 Americans live.

- Nearly 24,000 facilities release 5 billion kilograms of pollutants annually, with zinc, manganese, and lead compounds seeping into soil and water.

- Permafrost degradation will expose 1,100 more industrial sites by 2100, releasing long-trapped toxins into the environment.

Your awareness of these risks is essential as contamination continues to shape our landscape.

Remediation Costs Block Progress

Despite the urgent need to clean up industrial wastelands, remediation costs create significant barriers to progress.

You’ll find that cleanup technology expenses range dramatically – from basic soil capping at $50-200 per square meter to complex thermal treatments that can exceed $100,000 in capital costs alone. Initial site assessments start at $5,000 but quickly escalate for larger properties.

Remediation financing poses particular challenges for smaller landowners, as annual operating and maintenance costs can reach $50,000 or more.

You’re looking at substantial investments spanning multiple years, especially for manufacturing sites where complex contamination requires ongoing treatment. The emergence of new pollutants like PFAS further complicates matters, driving up costs through specialized treatment requirements.

These financial hurdles concentrate remediation projects in the hands of large, well-funded contractors while leaving many industrial wastelands untouched.

Site Monitoring Challenges Mount

When industrial sites fall into abandonment, monitoring their environmental and safety conditions becomes increasingly complex due to aging infrastructure and technological limitations.

You’ll find monitoring challenges intensified by antiquated sensor systems that can’t integrate with modern digital platforms, while harsh conditions constantly degrade equipment performance. Data integration becomes nearly impossible when information is scattered across incompatible systems and paper records.

- Corroding sensors struggle to transmit real-time data through failing power systems

- Legacy monitoring equipment sits disconnected from modern cloud platforms

- Unmonitored contamination zones spread beneath crumbling structures

Without reliable real-time monitoring, you’re facing increased risks from undetected gas leaks, structural failures, and spreading contamination.

Remote locations compound these challenges with poor connectivity, leaving critical environmental threats undetected until it’s too late.

New Life for Abandoned Industrial Parks

As abandoned industrial parks dot landscapes across the nation, savvy real estate investors are discovering lucrative opportunities to breathe new life into these dormant properties.

Today’s urban revitalization strategies focus on leveraging existing infrastructure, particularly sites with heavy power connections, rail access, and highway proximity. You’ll find adaptive reuse trends pointing toward data centers, advanced manufacturing, and logistics operations.

What makes these properties especially attractive is their ready-made infrastructure and large, contiguous parcels.

You’re looking at sites that often retain valuable public investments in utilities and transportation networks.

While environmental contamination and outdated systems pose challenges, developers are successfully transforming these spaces into modern business parks, technology hubs, and mixed-use developments that combine industrial, office, and retail components.

Future Prospects for Development Zones

While industrial construction activity remains substantial at 340.5 million square feet nationwide, you’ll notice a clear shift toward more sustainable development levels heading into 2026.

Future investment patterns suggest a strategic realignment, with construction deliveries projected to hit an 11-year low and site repurposing becoming increasingly attractive.

- Dallas-Fort Worth, Phoenix, and Houston are leading the development pipeline with 294 million square feet under construction, offering prime opportunities for strategic positioning.

- Modern facilities built after 2023 captured 57 million square feet of occupancy gains, demonstrating strong demand for updated infrastructure.

- Small-bay industrial spaces maintain sub-5% vacancy rates, indicating potential for targeted future investment in this undersupplied segment.

You’ll find the market’s evolution favors calculated, data-driven approaches to development rather than speculative building.

Frequently Asked Questions

How Do Local Communities Maintain Security at Abandoned Industrial Sites?

You’ll find communities implementing layered security through community surveillance networks, regular site monitoring patrols, physical barriers, CCTV systems, and coordinated responses between local law enforcement and property owners.

What Happens to Specialized Equipment Left Behind at These Facilities?

You’ll witness massive salvage operations strip these ghost factories bare – specialized equipment’s either auctioned off, preserved by liquidators, scrapped for raw materials, or left to rust in place.

Are There Successful Examples of Converting Industrial Wastelands Into Public Parks?

You’ll find remarkable urban revitalization successes like NYC’s High Line, Tel Aviv’s Ariel Sharon Park, and Germany’s Emscher Landscape Park, where ecological restoration transformed industrial wastelands into thriving public spaces.

How Long Does It Typically Take to Repurpose an Abandoned Industrial Site?

You’ll need 2-5 years from start to finish, beginning with site assessment through final redevelopment. The timeline depends heavily on contamination levels, regulatory requirements, and your project’s complexity.

What Role Do Local Historical Preservation Groups Play in Abandoned Site Decisions?

Like modern-day knights, you’ll find local preservation groups leading local advocacy efforts, implementing preservation strategies, partnering with stakeholders, securing funding, and influencing policy decisions to protect abandoned industrial heritage sites.

References

- https://underthehardhat.org/project-abandonments-report-2025/

- https://e2.org/releases/march-clean-economy-works-update/

- https://www.constructiondive.com/news/private-project-abandonments-record-high/750100/

- https://news.constructconnect.com/july-2025-sees-drop-in-project-stress-index-echoing-recovery-pattern-from-year-ago

- https://www.metalconstructionnews.com/news/may-starts-abandonments/

- https://www.bisnow.com/national/news/industrial/while-abandoned-industrial-sites-will-get-a-second-chance-tariffs-be-damned-129260

- https://www.constructiondive.com/news/abandonments-project-stress-constructconnect/744831/

- https://miamiairportwarehouses.com/abandoned-industrial-sites-could-get-a-second-chance-amid-shifting-manufacturing-demand/

- https://www.constructconnect.com/construction-economic-news/project-stress-index-march-2025

- https://safeguardproperties.com/zombie-foreclosures-remain-a-small-fraction-of-u-s-housing-inventory-in-first-quarter-of-2025/